As the name suggests, quality management in project management is all about ensuring that the project is delivered with high quality. This includes ensuring that the project meets all the requirements and is free of any defects. Quality management is a critical part of any project, as it can make the difference between a successful project and a failed one. By using the right quality tools you can greatly improve the chances of delivering the required quality to your stakeholders and clients.

Quality planning is a vital part of the project management toolkit. It ensures that your projects meet or exceed the expectations of your clients or decision-makers.

Many different project management tools are available, each with its strengths and weaknesses. Choosing the right tool for quality management is essential in meeting your needs and objectives.

Project Management is the application of knowledge, skills, tools, and techniques to project activities in order to meet or exceed stakeholder needs and expectations. Quality management is the process of making sure that a project meets all the necessary criteria for success. This includes things like meeting deadlines, staying within budget, and producing a product that meets the customer’s expectations.

- 17 of the most popular quality management tools:

- Six Sigma

- Fishbone Diagram

- Root Cause Analysis

- Check sheet template

- Control Chart

- Histogram

- Flowcharts

- Pareto Chart

- Scatter diagram

- Stratification

- Value Stream Mapping

- Process Flow Diagram

- Deming Cycle

- TQM

- Kaizen

- Affinity Diagrams

- Project Quality Management Beginners Guide

Understanding the quality tools….

There is no one-size-fits-all answer when it comes to quality management tools in project management. The most important thing is to select the tools that best fit the needs of your specific project.

There are a wide variety of quality management tools available, so it is important to take the time to select the ones that will be most useful for your project. These tools can be used to improve the quality of your project by identifying and eliminating errors and defects.

By using these quality tools, project managers can ensure that their projects are of the highest quality and that they meet the customer’s needs.

Why use quality management tools?

There are many benefits of using quality management tools in project management. Some of the benefits can include:

- Improve project quality metrics

- Increase customer satisfaction

- Reduce project costs

- Increase efficiency

- It takes your project to a level to be completed on time and within budget

- It helps to improve communication between project team members and stakeholders

- It identify and track risks

- It monitors efficiently while control the quality of deliverables

Quality management tools can be used at all stages of the project lifecycle, from planning to execution. By using quality management tools, project managers can increase the chances of success for their projects. There are a variety of quality management tools that can be used in project management.

17 of the most popular quality management tools:

Six Sigma

What is it?

- In organizations, the term “six sigma” describes a process or method that is extraordinarily efficient and effective. Six sigma has been used in various industries to streamline processes, reduce waste, and improve quality.

- This is a quality improvement methodology that can be used in a variety of different contexts, including project management which emphasizes the importance of understanding and reducing variation.

When to use?

- As it is a data-driven approach that seeks to remove defects and improve quality. Six Sigma can be used in any industry or organization, but it is most commonly used in manufacturing and service-based businesses.

- When used in project management, Six Sigma can help to ensure that projects are delivered on time and on budget. It can also be used to identify and solve problems that might otherwise cause delays or other issues.

Pros and Cons

- There are many advantages to using Six Sigma in project management. It can help to improve quality, reduce costs, and increase efficiency. Six Sigma can also help to improve communication and collaboration among team members.

- There are also some disadvantages to using Six Sigma. It can be time-consuming and expensive to implement, and it requires a high level of commitment from all team members. Six Sigma can also be inflexible, and it may not be the best approach for all projects.

Fishbone Diagram

What is it?

- A fishbone diagram is a tool used to help identify the cause of a problem. It is also known as a cause-and-effect diagram or an Ishikawa diagram. The diagram is structured like a fish skeleton, with the problem at the head and the various potential causes branching out from the spine.

When to use?

- They can be used to identify potential root causes of a problem so that corrective action can be taken to prevent the problem from occurring in the future.

Pros and cons

While fishbone diagrams are a valuable tool, they do have some drawbacks. For instance, they can be time-consuming to create, and they may not always identify all potential root causes of a problem. On the plus side, it helps you massively to see the relationship between different causes while the team additionally brainstorms unique solutions related to the root cause of a problem.

Pros:

- Organizes project management information in a clear and concise manner

- Easy to understand and use

Cons:

- It can be time-consuming to create

- It may require input from multiple people to be effective

- Opinion-based rather than evidence-based.

- It merely illustrates the problems rather than offering solutions

Root Cause Analysis

What is it?

- Root cause analysis (RCA) is a problem-solving technique used to identify the underlying cause of a problem. It is a process that is used to find out why a problem occurred and to prevent it from happening again.

When to use?

- Ultimately, the decision to use RCA or not will depend on the specific situation and the resources available. If you have a complex problem that needs to be solved, RCA may be the best tool for the job. For example, if you are experiencing a high rate of customer complaints, it may be helpful to use this method to identify the root causes of the issue.

Pros and Cons

- There are many advantages to using RCA, such as its ability to identify problems early on and its potential to save time and money. However, there are also some disadvantages to using this technique, including the possibility of human error and the need for expert knowledge.

Check sheet template

What is it?

- A check sheet is a structured, formatted tool that is used to collect data in quality assurance or manufacturing settings. It is used to track defects, problems, or wins across a process or project. Check sheets can be customized to track any type of information, and are often used in Six Sigma or other quality improvement initiatives.

When to use?

- Check sheets can be used to track any type of information, but they are most commonly used to track data that is numerical in nature.

Pros and Cons

- There are many advantages to using a check sheet. First, they are simple to use and understand. Second, they can be used to track a large amount of data in a short amount of time. Third, they can be used to track data over a long period of time. Fourth, check sheets can be used to identify trends and patterns. Finally, check sheets can be used to improve communication between team members.

- While check sheets are versatile quality tool, they do have some drawbacks. One disadvantage is that they can be time-consuming to set up and manage. Additionally, because they are often used in manufacturing or quality settings, they may not be well-suited for tracking other types of information.

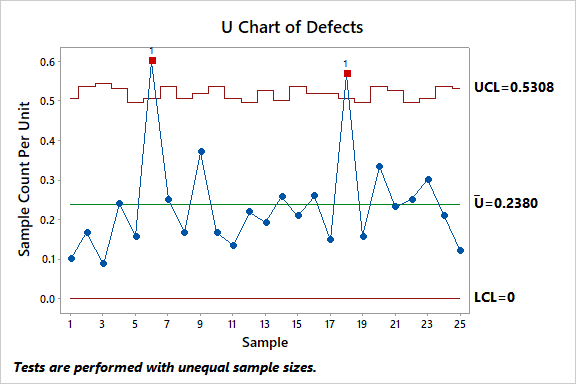

Control Chart

Control Chart

A control chart, also called Shewhart or Process Behavior Chart, is a graphical representation of data over time. The center line indicates the average of the plotted data, while upper and lower control limits are determined from the data.

You can use the control chart to monitor process variables, such as temperature, pressure, and weight. You can also use this project management tool to monitor product characteristics, such as dimensions and appearance.

Pros:

- It helps a project manager track data over time

- It can recognize the variations that are inherent in project management processes

- Enables you to develop new ideas to improve the quality based on your findings

Cons:

- Time-consuming to set up and maintain

- Uses data from the most recent measurement to come up with a conclusion

What is it?

- A control chart is a graphical tool used in project management to visualize process data and identify trends or patterns. The control chart can be used to track any process data but is most commonly used in manufacturing or quality control.

When to use?

- Control charts are most commonly used in manufacturing and quality control, but can be used in any process where there is variation. When used properly, control charts can be a powerful tool for improving process quality and preventing problems from occurring.

Pros and Cons

- There are both advantages and disadvantages to using a control chart in project management. Some of the advantages include its ability to help identify problems early on and its usefulness in tracking progress. Some of the disadvantages include its potential to create a false sense of security and its reliance on statistical data.

Histogram

A histogram visually represents data points that have been organized into user-specified ranges. This project management tool is similar to a bar chart, but with the histogram, you can take many data points and group them logically into bins or ranges.

What is it?

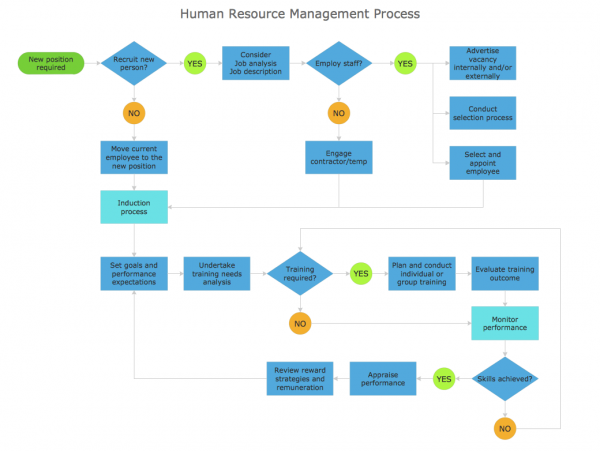

Flowcharts

A flowchart is a graphical representation of the steps and decisions required to carry out a procedure. It shows how steps in the project management process fit together. Just like Gantt charts, flowcharts are an excellent way to communicate the steps of a quality management plan or process clearly and concisely.

Each step in the project management sequence is marked with a symbol inside a diagram shape, and the connecting lines and directional arrows connect the steps. It is beneficial in project management as it allows you to examine the flowchart and follow the process from beginning to end.

Pros:

- Easy to create

- It makes the communication straightforward and effective

- The tool can help identify errors in the project management process

- It helps project managers create clear analysis

Cons:

- It can be challenging to present complex tasks and project management processes

- Do not allow modification or alteration

- It can be time consuming

The horizontal axis is the number range, while the vertical axis shows how much data is in each range. A histogram is often used in statistical analysis and quality management situations. A histogram is a graphical representation of data that shows how often each value occurs. They are easy to interpret and can provide a lot of information at a glance. They are also helpful for identifying outliers and unusual data points while it can help you to make proper decisions about resource allocation.

When to use?

Histograms are often used in project management to help visualize data and identify patterns. They can be used to track project progress over time, identify areas of concern, and spot future trends

Pros and Cons

Histograms have several advantages. They are easy to understand and can be used to quickly identify trends. Histograms can also be used to compare data sets, identify outliers, and spot patterns. There are some disadvantages to histograms as well. They can be difficult to interpret if the data is not evenly distributed. It can also be misleading if the data is not properly binned.

Pros:

- It helps you visualize the distribution of project management data

- It might represent a wide range of bars, representing various class intervals

- Easy to interpret

Cons:

- It can only display the continuous frequency distribution. It doesn’t include or show discrete data

- It doesn’t provide information like the median of data, upper quartile, lower quartile

Pareto Chart

A Pareto chart shows the relative occurrences of different values compared to one another. The bar height corresponds to an important unit of measure like frequency of occurrence or cost.

What is it?

This quality management tool combines features of both a bar chart and a line graph, with each bar representing a type of defect or problem, which helps you figure out where you should focus your attention for optimal improvement. A Pareto chart is a graphical tool used in quality management and project management to visually track and compare the relative importance of different factors. The Pareto principle, also known as the 80/20 rule, states that for many events, 80% of the effects come from 20% of the causes.

When to use?

It is mostly used when you need to identify which factors are having the most impact so that you can focus your efforts on the most important ones.

Pros and Cons

- It has some disadvantages that for example it can be quite time consuming but on the plus side there are more, for example, it can help you quickly identify which areas need the most improvement very understandable so you can easy interpret it, it can help you prioritize your resources and efforts and it can massively help you track your progress over time.

Pros:

- The project management tool helps determine the primary cause of a problem

- Organizes the problem from highest to lowest priority

- Provides a better explanation regarding difficulties you need to solve first

- It helps project managers solve issues concerning decision-making and time management

Cons:

- It only shows quantitative data

- It relies on past data to detect problems

- It helps evaluate issues but provides ways to solve them

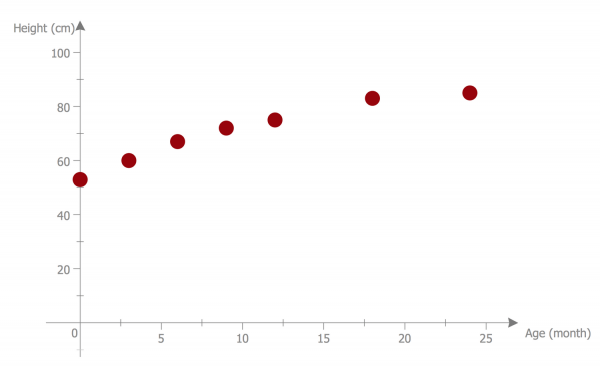

Scatter diagram

A scatter diagram is a visualization tool used in project management to understand the relationships between different variables. Scatter diagrams can be used to study the impact of one variable on another or to find out if there is a strong correlation between two variables.

What is it?

The scatter diagram, also known as a scatter plot chart, XY chart, or correlation chart, is a two-dimensional graphic depiction of a group of data. This project management tool plots pairs of numerical data against one variable on each axis to discover any link between them.

If the variables are linked, points will fall along the line or curve. The tighter the points hug the line, the better the relationship. Project managers usually use this project planning tool for root cause analysis.

When to use?

Scatter diagrams are often used in project management to study the impact of different factors on the project outcome. For example, a scatter diagram can be used to study the impact of project budget on the project timeline, or to show the relationship between project costs and project duration in general.

Pros and Cons

Scatter diagrams have some advantages and disadvantages. One advantage is that they can help to identify relationships between variables that would not be obvious otherwise. However, scatter diagrams can also be difficult to interpret, especially if there are many variables involved.

Pros:

- It helps project managers visualize the relationship between variables

- Scatter diagrams are simple to make or easy to plot

- It is easy to understand and interpret

Cons:

- It doesn’t include the degree of correlation, just the direction

- Useful for a small range of data points only

- Cannot show the relationship of more than two variables

Stratification

What is it?

Stratification is a project management technique that involves creating layers or levels within a project. This can be done by breaking down the project into smaller parts, or by creating distinct levels of hierarchy to give importance within the project.

When to use?

Stratification can be used when a project is very large or complex, or when there is a need to track and compare progress on different aspects of the project.

Pros and Cons

- It can help to simplify a complex project and make it more manageable, it can also help to prioritize tasks and objectives, which can make it easier to achieve project success and help you to track and compare progress, which can be valuable for identifying areas that need improvement (of course).

- However, stratification can also create its own set of problems. In particular, it can make it more difficult to communicate between different parts of the project, and it can lead to a feeling of disconnection among team members.

Value Stream Mapping

What is it?

- Value stream mapping is a tool that can be used in project management to help visualize the flow of work and identify inefficiencies. When used correctly, it can be a powerful tool to help optimize the project delivery process.

When to use?

- Value stream mapping should be used during the early stages of project planning, before work has begun. This will give you the clearest picture of the workflow. Also, Be sure to involve all stakeholders in the value stream mapping process, as it will be most effective when everyone is on the same page.

- It can be used in a variety of different projects, but it is especially useful in manufacturing and assembly projects. It can also be used in service industry projects, such as in health care or logistics.

Pros and Cons

- There are many advantages to using value stream mapping in project management. Perhaps the most significant advantage is that it can help to identify waste in a process. This is important because it can help to make a process more efficient and reduce the overall time and cost of a project.

- Despite the advantages, there are also some disadvantages to using value stream mapping. One disadvantage is that it can be time-consuming to create a value stream map. Additionally, value stream mapping is not always accurate and it may not be suitable for all types of projects.

Process Flow Diagram

What is it?

- This is a tool used in project management to visualize the relationships between different tasks in a project. It is similar to a flowchart, but it is more specific, emphasizing the order and the steps in a process.

When to use?

This quality tool is often used in engineering and manufacturing to document and communicate complex processes. They can also be used in other areas, such as project management, to map out the steps in a project in a clear and concise way.

This is typically used in the early stages of a project to create a high-level overview of the process. They can be used to identify potential bottlenecks and optimize the flow of the process.

Pros and Cons

- There are both advantages and disadvantages to using a process flow diagram in project management. Some of the advantages include its ability to visually represent the project flow, its flexibility, and its ability to be used in conjunction with other project management tools. Some of the disadvantages include its potential to be inaccurate and its potential to be misinterpreted.

Deming Cycle

What is it?

- The Deming cycle, also known as the PDCA cycle (plan-do-check-act), is a powerful tool that can be used to improve quality in any process. The cycle is designed to help organizations to identify and correct problems in their operations. It is a continuous cycle that can be used over and over again to help a business continuously improve its quality.

When to use?

- There are few situations when it can be very useful like; when you need to identify and correct problems early on in the project, when you want to improve the quality of your project, when you need to make sure that your project is on track or like when you want to assess the risks associated with your project

Pros and Cons

- There are many advantages to using the Deming cycle in project management. The most notable advantages are its ability to help organizations achieve their objectives, its focus on continuous improvement, and its ability to prevent problems before they occur.

- However, there are also some disadvantages to using the Deming cycle in project management. One drawback is that it can be time-consuming, especially if an organization is not used to using it. Another disadvantage is that it requires a high level of commitment from everyone involved in the project.

TQM

What is it?

- Total Quality Management, or TQM, is a project management technique that stresses continuous improvement and customer satisfaction. The goal of TQM is to reduce waste and errors in all aspects of a project, from planning to execution.

When to use?

- TQM can be used in any industry or type of project. However, it is most commonly used in manufacturing and construction projects. Also, it is often used in conjunction with other project management techniques, such as Six Sigma and Lean Manufacturing.

Pros and Cons

- One of the advantages of TQM is that it can help to improve the quality of a project by ensuring that all aspects of the project are considered. This can help to avoid potential problems and improve the overall outcome of the project.

- However, there are also some disadvantages of TQM. One of the main disadvantages is that it can be time-consuming to implement. Additionally, TQM requires all members of a project team to be involved, which can be difficult to achieve in some cases.

Kaizen

What is it?

- Kaizen is a Japanese word meaning “improvement.” In project management, kaizen refers to a continuous improvement process that involves all members of a project team. The goal of kaizen is to identify and eliminate waste in all aspects of a project, from the planning stage to the execution phase. It involves continual small improvements in all aspects of the company, from manufacturing to marketing to customer service.

When to use?

- Kaizen can be used in any type of project, but it is especially well suited for long-term projects with many moving parts. When used properly, kaizen can help a project run smoothly and efficiently on different industries from manufacturing to marketing to customer service

Pros and Cons

- Kaizen can be an effective project management tool because it helps to identify and eliminate waste, streamline processes, and improve quality. However, there are some potential drawbacks to using kaizen in project management.

For example, kaizen relies heavily on teamwork and collaboration, which can be difficult to achieve in a large organization. Additionally, kaizen can be time-consuming and may not always produce the desired results.

Affinity Diagrams

What is it?

- Affinity diagrams can be used to organize data collected from various sources, such as interviews, focus groups, brainstorming sessions, and survey. This tool can help to create a common understanding of the problem or issue at hand, identify relationships between ideas, and identify patterns

When to use?

- It is often used during the brainstorming phase of a project to help groups identify similarities and relationships between ideas. The affinity diagram can also be used to organize customer feedback or data from market research.

Pros and cons

When used properly it can help groups identify similarities and relationships between ideas and can increasingly help you to organize customer feedback or data from market research way more efficiently than other tools.

On the cons side, as many other quality tools we mentioned it can be time-consuming to create and you may require a facilitator to guide the process while it may be difficult to reach consensus among team members on the final organization of the ideas.

What are the 7 basic tools of quality management?

1. Fishbone

2. Scatter Diagram

3. Histogram

4. Check sheet

5. Pareto Diagram

6. Flowchart

7. Control Chart

What is the most commonly used tool in quality management?

Fishbone diagram, cause and effect diagram, and histogram are the most commonly used tools in quality management

Why are quality planning tools important?

Quality planning tools aid in fostering originality and problem-solving, and provide ongoing performance and customer satisfaction improvements.