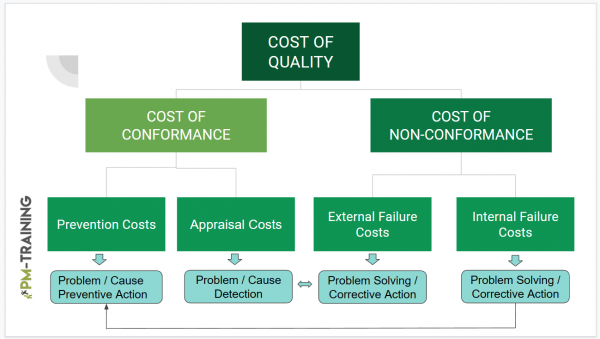

There are four major types of cost of quality in project management: prevention costs, internal failure costs, external failure costs, and appraisal costs. Prevention costs are associated with activities that prevent defects from occurring in the first place.

Internal failure costs occur when defects are found before the customer receives the product or service. External failure costs arise when the customer is the one who discovers the defects. Appraisal costs are associated with activities that measure the conformance of the product or service to quality standards.

An important part of project management is knowing how to identify and reduce the cost of quality in your project. By understanding the different types of costs of quality, you can put in place controls and procedures to reduce the incidence of defects and save your project money.

In project management, the cost of quality (COQ) is defined as a metric that captures the resources spent to achieve a certain level of quality.

The metric can be used to assess the cost of conformance ( resources spent to meet quality requirements) and the cost of non-conformance ( resources spent to fix defective products or services).

The COQ metric can be useful for project managers in a number of ways.

It can help them determine whether quality improvements are worth the investment, track the effectiveness of quality control measures, and identify areas where quality improvements are needed.

Benefits Of Cost Of Quality

There are a number of benefits to minimizing the cost of quality in project management.

These benefits include improved quality, increased customer satisfaction, and reduced costs.

In order to minimize the cost of quality, project managers need to be aware of the different types of costs and how they can be controlled.

4 Types Of Cost Of Quality

By investing in quality control measures such as inspection and testing, organizations can avoid costly mistakes that can lead to customer satisfaction issues, product recalls, and other problems down the line.

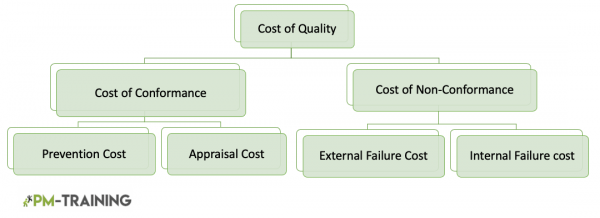

Cost of conformance

The cost of conformance (CoC) is the total amount of resources expended to ensure that a project meets quality requirements. In other words, it’s the cost of doing things right.

This includes the resources expended on quality assurance (QA) activities, such as inspections, audits, and testing.

The CoC is an important metric in project management because it can help you assess the financial impact of quality on your project.

By understanding the CoC, you can make decisions about trade-offs between quality and cost. For example, you might choose to accept a lower quality product if the cost of conformance is too high. Cost of conformance can be divided into Prevention cost and Appraisal cost

Prevention costs

Prevention costs are expenditures incurred to keep a product or system from failing. These costs are incurred in the design, development, and production phases of a project.

Prevention costs are often compared to appraisal costs and failure costs.

Appraisal costs are incurred to identify potential problems before they cause failures.

Failure costs are incurred when a product or system fails and must be repaired or replaced.

They are also known as avoidable costs or prospective costs. They are costs that can be avoided if proper measures are taken in the current phase of the project. Prevention costs are classified into two types: direct and indirect.

Appraisal cost

Appraisal costs are the costs incurred to determine the actual or expected value, quality, amount, or extent of something.

In project quality management, appraisal costs are the costs associated with assessing the quality of project deliverables.

Appraisal costs are often one of the largest project quality management costs.

They can vary widely in magnitude, depending on the number of appraisers involved, the length of time spent appraising, and the complexity of the project being appraised.

In some cases, appraisal costs can be incurred prematurely, before a project has had a chance to achieve its full potential.

When this happens, it can have a negative impact on the project’s budget and schedule.

Cost of nonconformance

In project management, the cost of non-conformance (CNC) is the financial penalty associated with producing an undesired outcome.

The cost can be actual or opportunity costs. In other words, it is the sum of all expenses that would have been saved had the project been completed satisfactorily.

CNC is often used as a metric to assess the success of a project. It is also a key element in quality management, as it can help to identify and correct deficiencies in the project management process. Cost of non conformance can be divided into external failure cost and internal failure cost

External failure cost

External failure costs are defined as the cost of poor quality that is incurred after the product or service has been delivered to the customer.

It includes the costs associated with warranty claims, repairs, replacements, and customer dissatisfaction.

External failure costs are often much higher than the cost of internal failures, which are the costs incurred during the manufacturing process.

Therefore, it is important for businesses to focus on preventing external failures in order to reduce costs and improve customer satisfaction.

One of the most effective ways to reduce external failure costs is to implement a project quality management system.

This system ensures that all aspects of the project are monitored and controlled in order to avoid any errors or defects.

Internal Failure costs

The internal failure cost includes the cost of resources used in detecting, diagnosing, and correcting the deficiency, as well as the opportunity cost of resources used for rework instead of other activities.

It also includes the cost of delays caused by the deficiency.

The Importance Of Each Cost In Your Projects

Cost of Conformance

This includes the cost of materials, the cost of labor, and the cost of compliance with regulations. The cost of conformance is often one of the most important factors in deciding whether or not to proceed with a project.

Prevention costs

Prevention costs are incurred to keep defects from happening in the first place. This can include things like training, quality control, and quality assurance. Prevention costs are most effective when they are targeted at the root causes of potential failures. By addressing the root causes, prevention costs can significantly reduce the likelihood of a failure occurring.

Appraisal costs

Appraisal costs are incurred to find defects that have already been caused. This can include things like testing, inspection, and audits.

The purpose of appraisals is to determine whether the product of the project meets the quality standards set for the project, and if not, to remedy the situations that led to the non-compliance.

Cost of nonconformance

This can include the cost of fixing errors, rework, and any other costs incurred as a result of not meeting the requirements.

CNC is important because it can have a major impact on the success of a project. If CNC is not managed properly, it can lead to higher costs and delays. Additionally, CNC can also impact the quality of the final product.

Different Cost of Internal Failure vs External Failure

Internal failure costs are incurred when defects are found before the product or service is delivered to the customer. This can include things like scrapped materials, rework, and repairs. External failure costs are incurred when defects are found after the product or service has been delivered to the customer. This can include things like warranty claims, customer returns, and legal damages.

This is an important concept in project quality management, as it can have a significant impact on the project budget. By understanding and managing external failure costs, project managers can avoid cost overruns and ensure the project is delivered on time and within budget.

FAQs

What is the Cost of quality?

The cost of quality is the price tag associated with ensuring that a project meets the required standards. This can include the cost of preventing, detecting, and correcting errors. The cost of quality can also be thought of as the cost of conformance to requirements.

How many types of cost of quality are there?

There are six types of cost of quality: cost of conformance, prevention costs, appraisal costs, cost of non-conformance, internal failure costs, and external failure costs.

What are the main benefits of Cost of Quality?

There are many benefits to incorporating Cost of Quality (CoQ) into project management. CoQ can help to increase the accuracy of budget estimates, improve project quality, and provide data for continuous quality improvement initiatives. Additionally, CoQ can help to identify potential problems early on in the project lifecycle, which can save time and money in the long run.

What is the importance of cost of quality in project management?

With the help of CoQ, organizations can improve the quality of their projects while also reducing costs. By understanding the cost of poor quality, project managers can make informed decisions that can help prevent potential problems and save the organization money.